- Home

- Products

- Candy Production Line

- Hard Candy Production Line

- Hard Candy Depositing Production Line

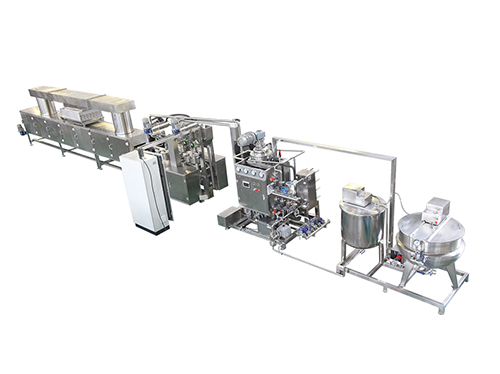

Hard Candy Depositing Production Line

Designed for manufacturing candies of various colors and types, such as two-color candy, filled candy, and spiral candy.

1200kg/hour

The hard candy depositing production line features a maximum capacity of a massive 1200kg/h.Efficient Production

The entire production process is computer controlled which ensures the finished candies are precisely the right size, shape, and weight.

This production line consists of an automatic weighing system, sugar dissolving cooker, liquid glucose storage, continuous vacuum cooker, servo-driven depositing machine, cooling tunnel, and demolding device.

- Automatic weighing system

- Sugar dissolving cooker

- Liquid glucose storage

- Continuous vacuum cooker

- Servo-driven depositing machine

- Cooling tunnel

- The heating time, heating temperature, depositing time and depositing speed is controlled by computer.

- A 10.7 inch touch screen displays various parameters including flow charts, the status of each part of the production line, temperature, depositing speed, etc.

- Flow of the syrup is precisely controlled by frequency control system that ensures stability.

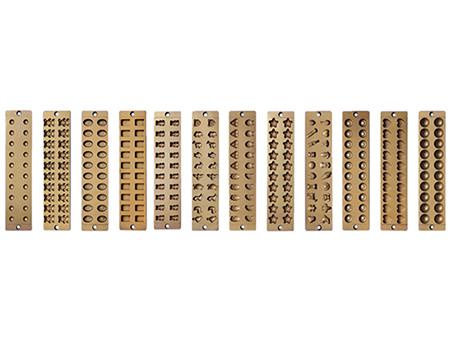

- By simply changing molds and other parts of the production line, it can be used to produce hard candies of various shapes, such as spherical hard candies, flat hard candies, and 3D hard candies.

- It is easy to operate and maintain.

- The production line can be customized to fit your operation perfectly.

-

Dissolving and mixing unit with automatic weighing system

It can automatically mix and dissolve glucose, granulated sugar, and other ingredients. The amount of the ingredients is precisely controlled by PLC.

-

Continuous vacuum cooker

It features automatic temperature control, high output, short cooking time, and can manufacture high-transparency syrup.

-

Mold

The production line can manufacture candies of various shapes using different molds. We can design the molds for you according to your desires.

-

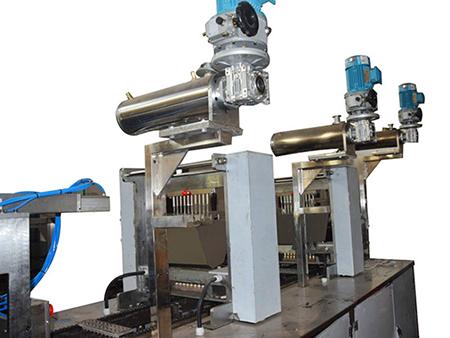

Depositing machine

Each depositing machine is comprised of a depositing head, mold, and refrigerated cooler. The depositing head comes equipped with a double hopper. By replacing the stamping board and nozzle, the machine can be used to produce filled hard candy and two-color hard candy. It uses PLC to control the parameters such as temperature and depositing speed. These parameters are displayed and adjusted via the machine’s touch screen. The flow of the syrup is controlled with great precision using the frequency control system to ensure stable quality.

We are the original hard candy depositing production line manufacturer in China. Our production lines have been applied and praised by many customers around the world. Contact us to learn more.

-

Q: Are you a factory?

A: We are factory, and have obtained ISO9001 certificate with the certificate number of 10135145Q. In addition, each of our products has CE certificate.

-

Q: What after-sales service do you provide?

A: (1) Video guide (2) Online guide (3) On-site installation and maintenance.

-

Q: What are the machines made of?

A: All materials are made of 304 stainless steel.

-

Q: How long is the lead time?

A: The delivery time is generally 10 days to 35 days depending on the machines.

-

Q: Do you provide factory test service?

A: Before leaving the factory, each machine will be tested and shipped only after the customer is satisfied.

-

GD1200S This hard candy depositing production line is a fully automatic production line equipped with a double depositing head. Its maximum capacity is 1200kg/h which can meet the requirements of large-scale candy producers.

-

GD450 This hard candy depositing production line provides a maximum capacity of 450kg/h. It is suitable for small-scale candy factories.

-

Die-Formed Hard Candy Production Line

This die-formed hard candy production line is designed to produce various shapes of candies utilizing different molds.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer