- Home

- Products

- Candy Production Line

- Toffee Candy Production Line

Toffee Candy Production Line

TG Machine’s toffee candy production line is fully automatic, carrying out all processes from raw material preparation to toffee candy formation to save labor costs. It is used in the production of different toffee candies, including single-color toffee, double-color toffee, filled toffee candies, striped toffee and other toffee types. Our production lines are also customized to fit specific customer factory layouts and special requirements.

-

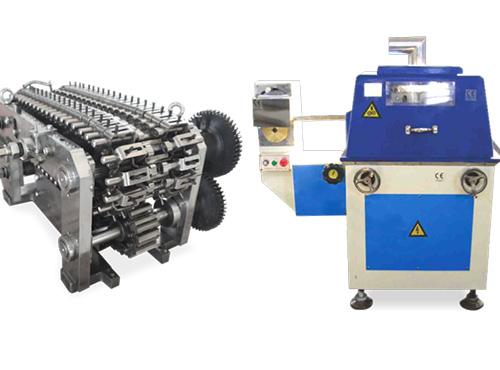

- Die-Formed Toffee Candy Production LineThe die-formed toffee candy production line is comprised of the toffee cooking machine, caramel cooking machine, pulling machine, jam pump, candy extruder, chain type forming machine, shaking distribution conveyor, cooling conveyor and the refrigerated cooler, thus facilitating the manufacturing of different toffee candies, including soft filled toffee, filled toffee (eclairs) and caramels.

-

- Toffee Candy Depositing Production LineThe toffee candy depositing production line is designed to manufacture a variety of toffee candy types, including single-color toffee candy, two-color toffee candy, filled candy, and more. Through the use of different molds, different candy shapes are made through a highly automatic production process. This level of automation also saves labor costs.

-

- Central-Filled Soft Chewy Candy Production LineThe T300 central-filled soft chewy candy production line is one of TG Machine’s main products. It was designed and developed in response to market changes and an increase in demand for candy with low sugar, excellent taste, variety and better nutritional value. The technology, mechanical behavior and technical indexes of this chewy candy production line meets advanced international standards for performance and reliability.

Why you choose TG Machine’s production line?

- Only high-quality materials and parts sourced from trusted brands are used to ensure the reliability and high output of the equipment.

- The high level of automation eliminates the risks posed in manual operation, such as unqualified products and safety concerns.

- Each production line is designed according to the actual layout and operation of your factory so as to meet your special requirements.

- All our production lines are designed and manufactured in a way that meets GMP requirements. They can also meet the quality standards of your country.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer