- Home

- Products

- Biscuit Production Line

- Multifunction Biscuit Production Line

Multifunction Biscuit Production Line

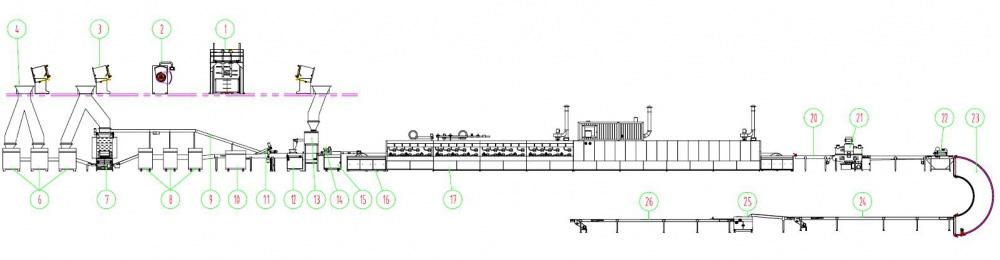

The multifunctional biscuit production line is designed to produce both hard and soft biscuits. To meet unique customer requirements, TG Machine offers a variety of multifunctional biscuit production lines in different configurations and capacities, with a maximum capacity of 1500kg/hour.

In addition, we also offer a variety of biscuit mold shapes for the production of different biscuit shapes.

- The production line runs continuously for a high production capacity and quick recoup on initial investment costs.

- It is a fully automatic production line requiring very minimal human interference.

- Through the use of different, easy to change molds, the production line produces a variety of biscuit types.

- We will customize mold for you according to your requirements.

- The production line components are manufactured here in house to ensure quality and a quick supply of spare parts.

- Vertical dough mixer

- Horizontal dough mixer

- Material feeder

- Dough conveyor

- Laminator

- Dough roller

- Material recycling device

- Roll cutting machine

- Rotary molder

- Divider

- Condiment spreader

- Furnace charging conveyor

- Wire mesh belt conveyor

- Tunnel oven

- Furnace discharge conveyor

- Oil spray machine

- Vibrating spreader

- Turning conveyor

- Cooling conveyor

- Star wheel stacker

- Picking conveyor

- Packaging machine

-

Dough mixer

The dough mixer is designed to mix different dough types with a maximum capacity of up to 500kg. This machine is customizable according to your requirements.

-

Condiment spreader

This machine is designed for spreading condiments such as salt, sugar, sesame seeds, and nut slices on the biscuit blank surface to improve the taste.

-

Material recycling device

It is designed to recycle rest material after hard biscuit formation.

-

Furnace charging conveyor

This machine conveys the formed biscuit blank to the oven while rejecting any that are unqualified. It will also recycle unused condiments such as salt, sugar, sesame seeds, and nut slices.

-

Laminator

The laminator completes stressing, powdering, and laminating processes to create layered biscuits. The dough width and dough sheet layers are easy to set, while parameters such as speed and dough thickness are clearly displayed on the screen.

-

Rolling machine

The laminator completes stressing, powdering, and laminating processes to create layered biscuits. The dough width and dough sheet layers are easy to set, while parameters such as speed and dough thickness are clearly displayed on the screen.

-

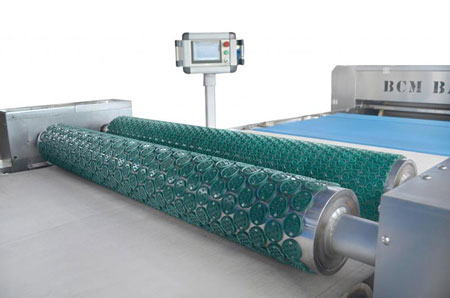

Forming machine

The forming machine is designed to form different biscuit types. It carries out a variety of processes, including printing, forming, and demolding. Material feeding and forming speed are both adjustable, while parameters such as speed and distance between the roller and roller mold are clearly displayed on screen. The conveyor belt is equipped with an automatic tensioning device and automatic deviation rectifying device to ensure a reliable conveyance performance.

-

Tunnel ove

The tunnel oven is designed for baking biscuits, breads, cakes, and other doughy foods. We offer a variety of tunnel ovens for the production of different biscuit types, including hot air circulating ovens, wood or gas fired ovens, and infrared ovens. The tunnel oven’s length and width are customizable according to customer requirements.

-

Oil spray machine

The oil spray machine carries out a high speed, foggy oil spray on biscuits to improve luster, flavor and taste. The oil tank is warmed via electric heated water and an adjustable temperature. The oil spray machine uses a filter to recycle used oil after spraying, and is made of 304 stainless steel for an excellent cleanliness and hygienic performance.

-

Conveyor equipment

-

Conveyor equipment

-

Conveyor equipment

-

Q: Are you a factory?

A: We are factory, and have obtained ISO9001 certificate with the certificate number of 10135145Q. In addition, each of our products has CE certificate.

-

Q: What after-sales service do you provide?

A: (1) Video guide (2) Online guide (3) On-site installation and maintenance.

-

Q: What are the machines made of?

A: All materials are made of 304 stainless steel.

-

Q: How long is the lead time?

A: The delivery time is generally 10 days to 35 days depending on the machines.

-

Q: Do you provide factory test service?

A: Before leaving the factory, each machine will be tested and shipped only after the customer is satisfied.

-

Biscuit Production Line by Bangladesh Customer

Time: October, 2018

Customer Location: Bengal

This large customer purchased a hard candy production line from TG Machine five years ago. They were so happy with the performance of that line that they came to us again as they were looking to expand into biscuit production.

-

Soft Biscuit Production Line

TG Machine offers a variety of equipment for soft biscuit production lines, designed to meet GMP food hygiene standards and customer requirements regarding different soft biscuit types.

-

Hard Biscuit Production Line

TG Machine provides a variety of hard biscuit production lines in different configurations and capacities to meet specific requirements, with a maximum capacity of 1250kg/hour.

In addition, we also provide an array of molds for the production of different biscuit shapes.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer