- Home

- Case Study

- Chocolate Production Line by Albania Customer

Chocolate Production Line by Albania Customer

Customer Location: Albania

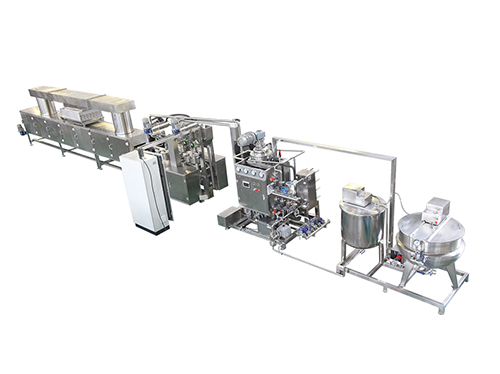

This customer operates a factory in Albania and was looking to manufacture chocolate wafers.

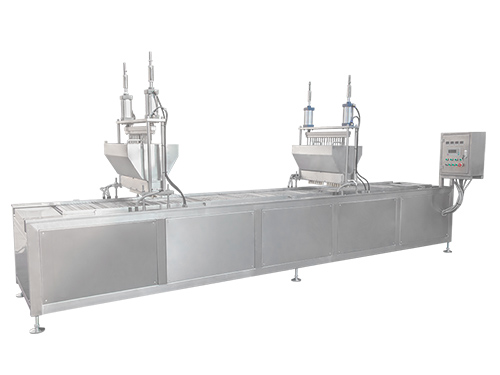

We made an equipment list based on the samples provided by the customer’s agent. The coating part of the production line would consist of a 500L chocolate fine grinding machine, 500L chocolate stock tank, and chocolate coating machine. The wafer manufacturing section of the production line would feature an egg mixer, material feeder, forming machine, wafer cutting machine, and cream spreading device. Siemens supplies the motor and electrical components of the equipment.

After confirmation, we put the equipment into production and invited the customer to our factory. They were satisfied and we shipped the equipment along with installation guidance videos as they did not need on-site installation services. The customer returned to tell us that their production line was running smoothly and that they were looking to purchase a second production line to expand their mass production capabilities.

We have continuously improved our products to meet customer requirements for more than two decades. We look forward to the opportunity to cooperate with you.

-

Handmade Marshmallow Depositing Machine

The KT-10 handmade marshmallow depositing machine uses plastic molds for marshmallow production.

-

Die-Formed Hard Candy Production Line

This die-formed hard candy production line is designed to produce various shapes of candies utilizing different molds.

-

Hard Candy Depositing Production Line

Designed for manufacturing candies of various colors and types, such as two-color candy, filled candy, and spiral candy.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer