- Home

- Products

- Candy Production Line

- Gummy Candy Production Line

- Gummy Candy Depositing Production Line, GD600Q

Gummy Candy Depositing Production Line, GD600Q

The gummy candy depositing production line is designed to manufacture gummy candy in a variety of shapes.

600kg/hour

Its PLC-controlled design enables it to have a maximum capacity of 600kg/hour.Food Safety

The candy production line is designed to ensure food safety and meet GMP standards in every process.Production Flexibility

With different configurations, the candy production line is able to produce different types of gummy candies, such as single-color ones, two-color ones and striped ones as well as other types.Save Space and Labor Costs

This candy production line features a compact structure and highly automated performance, which helps cut costs while producing quality goods.

-

Pectin gel mixing system

It is equipped with an automatic ingredient weighing and mixing system for the pre-cooking of pectin slurry, during which the pectin powder, sugar powder and water are mixed evenly. It can make finished candies taste better even though they are of different qualities at the beginning caused by varieties of raw materials. A single stainless steel weigh tank is mounted on three load cells designed for 180kg in weight at maximum. After the weighing, all of the materials will enter the jacketed cooker that is equipped with a high-speed shear, in which the pectin powder and powdered sugar will be fully dissolved. Once the ingredients are moved into the vessel, the syrup will be transferred to the holding tank for the next step of production. The storage tank is a holding vessel for hot or cold liquids and slurries. The whole machine is equipped with several highly-automated components, for example, a stainless steel stirrer and a self-draining base. Apart from that, washing is quite easy since the stainless steel framework can be washed directly. All pipes are equipped with tubular filters, which can eliminate impurities in the liquid to ensure the syrup is clean so as to meet health and safety standards. Plus, up to ten pre-set recipes are stored in the PLC control system.

-

Syrup and gel weighing and mixing system

The process starts with weighing and mixing of the main ingredients with water, sugar powder, gulcose, dissolved gel. The ingredients are fed in a row into a gravimetric weighing and mixing tank and the quantity of ingredients is adjusted according to the actual weight of the existing ones. In this way, an accuracy of 0.1% of weight is achieved, ensuring quality of finished products and consistency of production. Active ingredients can also be added at this stage. Each batch of ingredients is mixed with slurry and then fed to a reservoir tank and later fed to the cooker. The weighing and mixing cycle is fully automatic and complete records of every batch are available in the control system, which is connected to factory network, meaning that you can know the records remotely.

-

Advance raising film continuous cooker

Cooking involves two steps. Firstly, granulated sugar or isomalt will be dissolved. Secondly, syrup will be evaporated in order to produce finished goods. The cooking will be completed in the cooker since its shell and tube is equipped with scrapers. This is a simple venturi-style device that subjects the cooked syrup to a sudden drop in pressure, causing excessive moisture to flash off. The partially-cooked syrup enters the microfilm cooker and passes the steam-heated tube inside the cooker. The surface of the cooker tube is scraped by multiple blades to form a very thin film of syrup that can be cooked in a matter of seconds as it passes down the tube into a collecting chamber. Cooking temperature is reduced after the cooker is in vacuum. Rapid cooking at the lowest possible temperature will avoid heat degradation and process inversion, which will undermine the clarity of the candies and cause shelf problems such as stickiness and cold flow.

-

CFA and active ingredients mixing system

Colors, flavors and acid (CFA) are added to the syrup after cooking and it is at this point that the active ingredients will be added through a similar system. The basic CFA addition system comprises a holding tank and a peristaltic pump. Mixing, which takes three to five minutes for 40-50L of ingredients, heating and recirculation will be carried out to keep the additions in optimum condition. A flowmeter control loop will also be loaded on the pump for ultimate accuracy. After adding all ingredients into the weighing system, two sensors-equipped tanks inside the system make candies with two colors possible. The weighing system will ensure an accurate quantity of ingredients, and the mixed ingredients won’t be affected by voltage variation, flow variation and different recipes.

-

Depositing

A depositor comprises a depositing head, mold circuit and cooling tunnel. The cooked syrup is held in a heated hopper embedded with a large number of separate ‘pump cylinders’—one cylinder powers one deposit. The cooled syrup is then drawn into the body of the pump cylinder by upward motion of a piston and pushed through a ball valve on the downward stroke. The mold is moving continuously and the whole depositing head reciprocates back and forth to track the mold’s movement. All of the movements in the head are servo-driven for accuracy and linked mechanically for consistency.

-

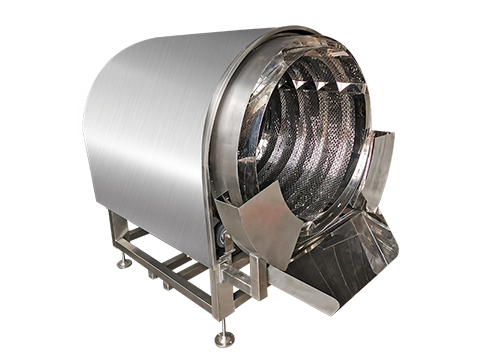

Cooling Unit

A two-pass cooling tunnel is located after the depositor with ejection under the depositor head. To cool candies, air will be drawn from factory and circulated through the tunnel by multiple fans. After that, the candies should be refrigerated. When the candies emerge from the cooling tunnel, they are finished products.

- The flavors and color mixing system uses a dosing pump and dynamic mixer manufactured by LMI MILTON (American brand) to ensure the mixed syrup is uniform in color. The food coloring and flavoring amount is adjustable according to your needs.

- The improved depositing head is more reliable and accurate.

- The punch is easy to operate and replace. The punch stroke (sugar weight) is adjustable online.

- The hopper uses electric heating with an easily adjustable temperature.

- Its improved cooling tunnel features the same height, longer length and more accurate temperature control over previous models. The full refrigeration unit is integrated into the refrigerated cooler.

- The unique demolding device features a tank chain structure and is equipped with a rotating brush to ensure a full candy demolding process.

- Its PVC cooling conveyor belt is manufactured using the latest technology. It features a smooth appearance and is easy to clean and maintain, ensuring a long service life.

- The production line can be customized to fit your site conditions.

-

Q: Are you a factory?

A: We are factory, and have obtained ISO9001 certificate with the certificate number of 10135145Q. In addition, each of our products has CE certificate.

-

Q: What after-sales service do you provide?

A: (1) Video guide (2) Online guide (3) On-site installation and maintenance.

-

Q: What are the machines made of?

A: All materials are made of 304 stainless steel.

-

Q: How long is the lead time?

A: The delivery time is generally 10 days to 35 days depending on the machines.

-

Q: Do you provide factory test service?

A: Before leaving the factory, each machine will be tested and shipped only after the customer is satisfied.

-

Gummy Production Line by US Customer

Time: August, 2018

Customer Location: American

Gummy vitamins have been increasing in popularity in recent years, particularly in America and Canada. Addressing the needs of producers of health products, we have been supplying production lines specially designed to manufacture gummy and vitamins.

-

Jelly Candy Starch Mogul Line

The jelly candy starch mogul line is designed for producing starch jelly candy. It is PLC controlled and features a maximum capacity of 400 to 800kg/hour.

-

Gummy Candy Depositing Production Line, GD150Q

The gummy candy depositing production line is designed to manufacture gummy candy in a variety of shapes. It is PLC controlled and features a maximum capacity of 600kg/hour.

-

Gummy Candy Depositing Production Line, GD40Q

GD40Q Automatic gummy production system is very compact, with specifications of L (10m) * W (2m), meaning that it is quite suitable for small- and medium-size companies.

-

Gummy Candy Depositing Production Line, GD80Q

GD80Q Automatic gummy production system is very compact, with specifications of L (13m) * W (2m), meaning that it is quite suitable for small- and medium-size companies.

-

Gummy Candy Depositing Production Line, GD300Q

GD300Q Automatic gummy production system is very compact, with specifications of L (14m) * W (2m), meaning that it is quite suitable for small- and medium-size companies. Despite that, it is highly productive, as evidenced by its production rate at 85,000 gummy candies per hour, during which the whole process will be completed, including cooking, depositing and cooling.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer