- Home

- Products

- Candy Production Line

- Gummy Candy Production Line

- Jelly Candy Starch Mogul Line

Jelly Candy Starch Mogul Line

The jelly candy starch mogul line is designed for producing starch jelly candy. It is PLC controlled and features a maximum capacity of 400 to 800kg/hour.

It uses a servo motor to convey pallets, and features a low start speed, low speed brake, high speed operation, a smooth operation and excellent work efficiency.

-

Jacketed cooking kettle

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

-

Mold

The production line manufactures candies in a variety of shapes using different molds. We will design molds according to your needs.

-

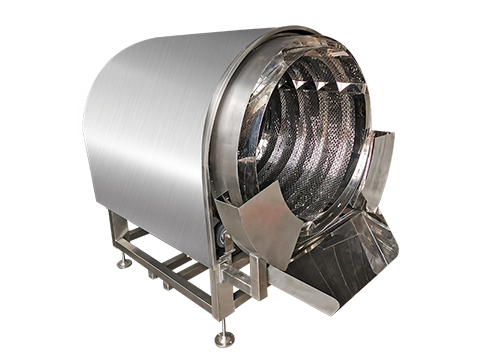

Starch molding machine

The depositing machine uses PLC to control the parameters such as temperature and depositing speed. These parameters are easy to read and set on the touch screen, while the syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

-

Q: Are you a factory?

A: We are factory, and have obtained ISO9001 certificate with the certificate number of 10135145Q. In addition, each of our products has CE certificate.

-

Q: What after-sales service do you provide?

A: (1) Video guide (2) Online guide (3) On-site installation and maintenance.

-

Q: What are the machines made of?

A: All materials are made of 304 stainless steel.

-

Q: How long is the lead time?

A: The delivery time is generally 10 days to 35 days depending on the machines.

-

Q: Do you provide factory test service?

A: Before leaving the factory, each machine will be tested and shipped only after the customer is satisfied.

-

Gummy Production Line by US Customer

Time: August, 2018

Customer Location: American

Gummy vitamins have been increasing in popularity in recent years, particularly in America and Canada. Addressing the needs of producers of health products, we have been supplying production lines specially designed to manufacture gummy and vitamins.

-

Gummy Candy Depositing Production Line, GD150Q

The gummy candy depositing production line is designed to manufacture gummy candy in a variety of shapes. It is PLC controlled and features a maximum capacity of 600kg/hour.

-

Gummy Candy Depositing Production Line, GD40Q

GD40Q Automatic gummy production system is very compact, with specifications of L (10m) * W (2m), meaning that it is quite suitable for small- and medium-size companies.

-

Gummy Candy Depositing Production Line, GD80Q

GD80Q Automatic gummy production system is very compact, with specifications of L (13m) * W (2m), meaning that it is quite suitable for small- and medium-size companies.

-

Gummy Candy Depositing Production Line, GD300Q

GD300Q Automatic gummy production system is very compact, with specifications of L (14m) * W (2m), meaning that it is quite suitable for small- and medium-size companies. Despite that, it is highly productive, as evidenced by its production rate at 85,000 gummy candies per hour, during which the whole process will be completed, including cooking, depositing and cooling.

-

Gummy Candy Depositing Production Line, GD600Q

GD600Q Automatic gummy production system is large and sophisticated, which is especially suitable for large companies. It is equipped with automatic weighing and automatic feeding devices, which boost productivity and reduces labor cost.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer