- Home

- Products

- Candy Production Line

- Sucker Production Line

- Die-Formed Sucker Production Line

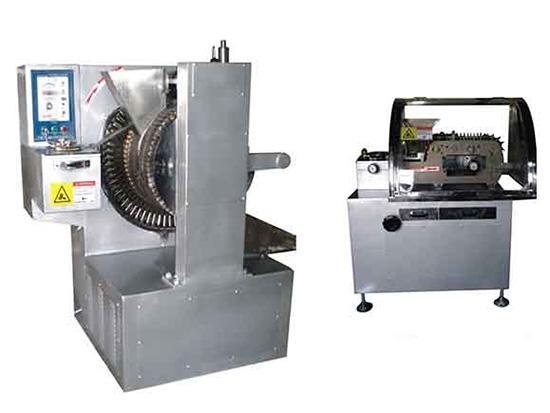

Die-Formed Sucker Production Line

The die-formed sucker production line produces suckers in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different sucker shapes.

400kg/hour

It features a maximum capacity of 400kg/hour.Reduced Material Waste

This advanced sucker production equipment effectively reduces material waste.Good Quality Lollipop Production

Die-formed lollipop production line is equipped with an electric heating cooker to ensure an even PLC controlled heating time and temperature, ensuring the sucker is transparent and features a good taste.

Backed by extensive experience, not only do we offer customized die-formed sucker production lines, but we also offer the matched molds.

- Sugar dissolving cooker

- Liquid glucose storage

- Continuous vacuum cooker

- Cold table

- Batch roller

- Rope sizer

- Die forming machine

- Shaking distribution conveyor

- Refrigerated cooler

- The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

- The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

- Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

- By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.It is easy to operate and maintain.

- The production line can be customized to fit your site conditions.

-

Continuous vacuum cooker

It features an automatic temperature control and high output performance that saves time with its short cooking process. Syrup manufactured using this cooker features an excellent transparency.

-

Forming machine

The forming machine is designed to manufacture hard candy in different specifications. It can be modified to produce hard candy in a variety of shapes according to your needs.

-

Q: Are you a factory?

A: We are factory, and have obtained ISO9001 certificate with the certificate number of 10135145Q. In addition, each of our products has CE certificate.

-

Q: What after-sales service do you provide?

A: (1) Video guide (2) Online guide (3) On-site installation and maintenance.

-

Q: What are the machines made of?

A: All materials are made of 304 stainless steel.

-

Q: How long is the lead time?

A: The delivery time is generally 10 days to 35 days depending on the machines.

-

Q: Do you provide factory test service?

A: Before leaving the factory, each machine will be tested and shipped only after the customer is satisfied.

-

YT200L Die-formed hard candy production line This production line is cost-effective and suitable for small-scale candy plants. Its capacity is 100-200kg/h.

-

YT400L Automatic die-formed hard candy production line This automatic production line is equipped with a vacuum cooker to effectively reduce syrup temperature, ensuring it is more transparent and increases the hard candy quality.

-

Sucker Depositing Production Line

The sucker depositing production line produces 3-color suckers, as well as ball and double-ball suckers in a layered or striped style. Compared to the die-formed sucker production line, this equipment set features a smoother product surface and smaller labor costs. It is ideal for sucker mass production.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer