- Home

- Products

- Candy Production Line

- Sucker Production Line

- Sucker Depositing Production Line

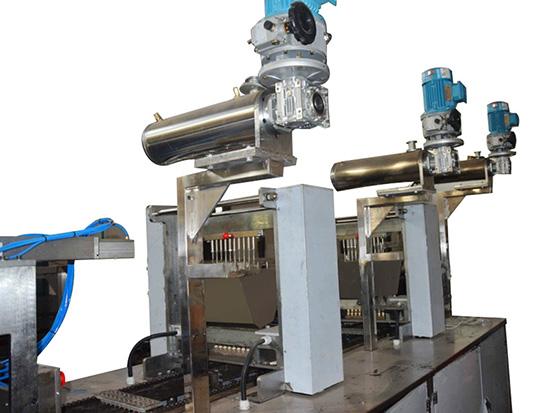

Sucker Depositing Production Line

The sucker depositing production line produces 3-color suckers, as well as ball and double-ball suckers in a layered or striped style. Compared to the die-formed sucker production line, this equipment set features a smoother product surface and smaller labor costs. It is ideal for sucker mass production.

Quality Manufacturing

Suckers manufactured using this line is extremely popular due to their clear strip, precise amount and position of filled materials.High Food Safety

The entire production line is manufactured to meet GMP and food safety standards, ensuring it is easier for your company to pass GMP, QS and HACCP certifications.

- The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

- The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

- Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

- By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.

- A chocolate depositing system is optional for use in the production of chocolate filled suckers.

- Simply change a few parts and molds, and the production line becomes suitable for the production of hard candy.

- The production line can be customized to fit your site conditions.

-

Vacuum microfilm cooker

It features an automatic temperature control and a high output, ensuring the short cooking period saves time without sacrificing syrup transparency.

-

Mold

Through the use of different molds, this production line manufactures different suckers, including ball suckers, double-ball suckers, and flat suckers. We will design molds according to customer needs.

-

Depositing machine

The depositing machine is composed of the depositing head, mold, and refrigerated cooler. The depositing head is equipped with double hopper and by replacing the stamping board and nozzle, this equipment is used for the production of filled suckers and two-color suckers. It uses PLC to control different parameters, such as temperature and depositing speed. These parameters are easily set and displayed on the touch screen. Syrup flow is also precisely controlled using a frequency control system to ensure sugar paste quality.

-

Q: Are you a factory?

A: We are factory, and have obtained ISO9001 certificate with the certificate number of 10135145Q. In addition, each of our products has CE certificate.

-

Q: What after-sales service do you provide?

A: (1) Video guide (2) Online guide (3) On-site installation and maintenance.

-

Q: What are the machines made of?

A: All materials are made of 304 stainless steel.

-

Q: How long is the lead time?

A: The delivery time is generally 10 days to 35 days depending on the machines.

-

Q: Do you provide factory test service?

A: Before leaving the factory, each machine will be tested and shipped only after the customer is satisfied.

-

Die-Formed Sucker Production Line

The die-formed sucker production line produces suckers in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different sucker shapes.

-

- No.100 Qianqiao road, Fengxian district, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

- +86-19121873586

-

- GD600 Hard Candy Production Line in the US

- Popping Boba Production Line in Russia

- Popcorn Production Line in the US

- Functional Gummy Production Line in Bangladesh

- Marshmallow Production Line in Iraq

- Upgraded Gummy Production Line in the US

- Gummy Production Line by US Customer

- Chocolate Production Line by Albania Customer

- Toffee Candy Production Line by Egypt Customer

- Biscuit Production Line by Bangladesh Customer